SolutionsProducts

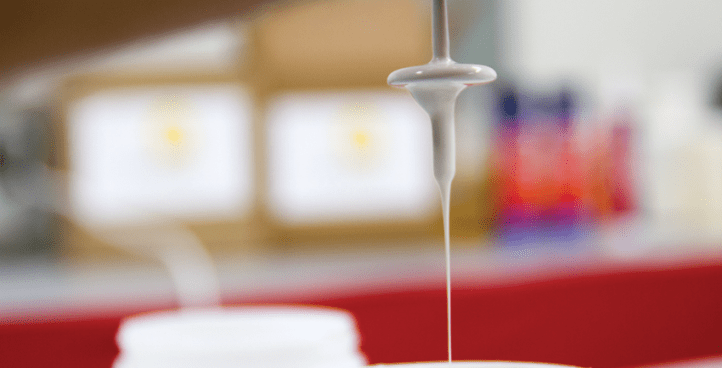

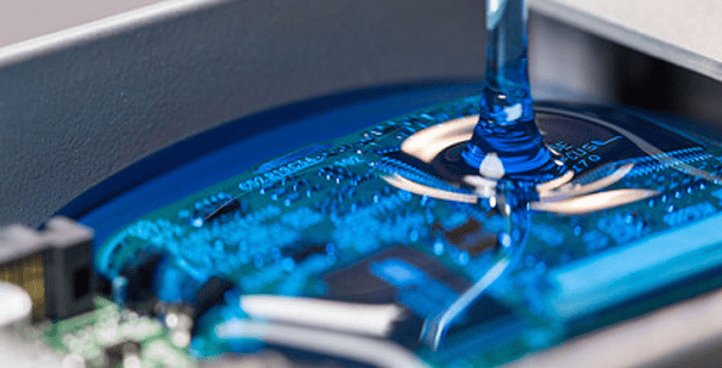

To provide you with high-quality, worry-free products, APPLIED Adhesives partners with world-class industry leaders for the most innovative and cost-effective adhesive products.

SolutionsMarket Segments

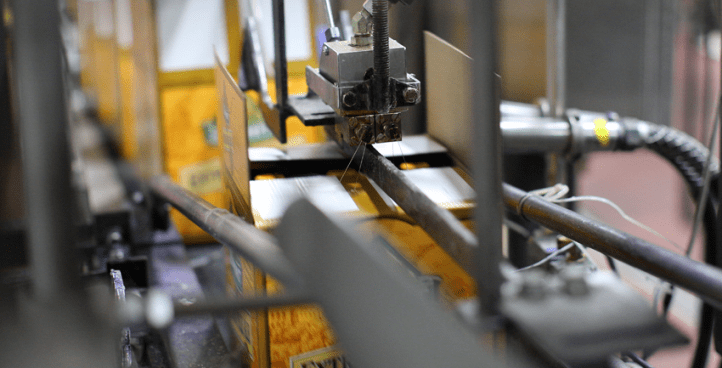

Your business and industry have distinct adhesive needs. Whatever the market, manufacturing process, substrate, or end use, APPLIED can connect you with the right adhesive for the job.

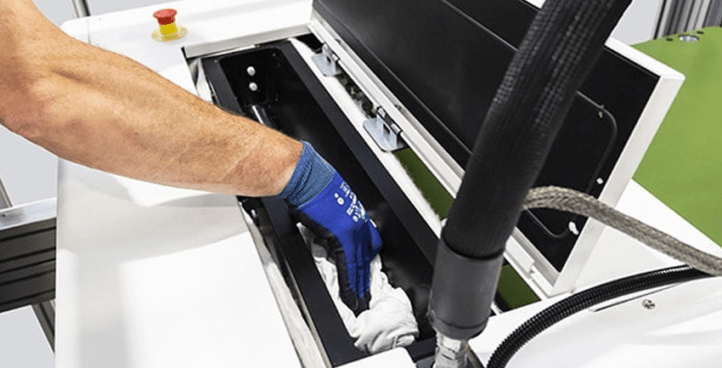

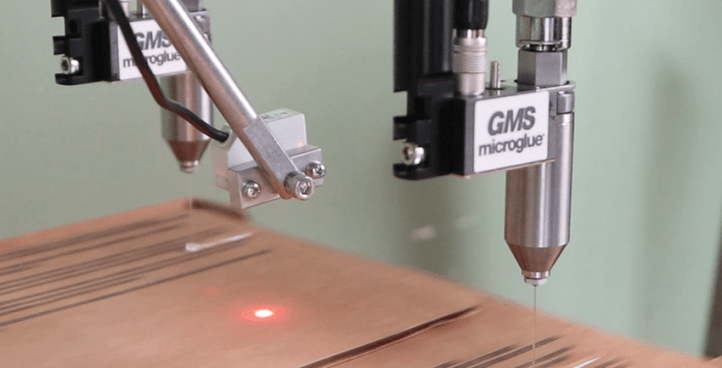

SolutionsEquipment

With state-of-the-art, efficient, and safety-first technology from leading manufacturers on your production lines, APPLIED delivers the adhesive equipment you need to achieve goals for speed, value, precision, and quality.

SolutionsSecure Your Adhesive Supply Chain

Find out how APPLIED is prepared to keep your production lines running efficiently.